Precision Cooling

Quick Summary:

A. Develop our own control methodology based on over 28 years HVAC experiences

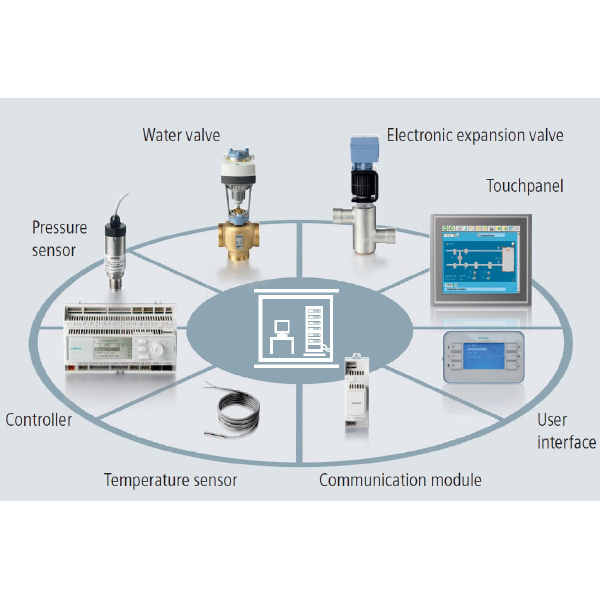

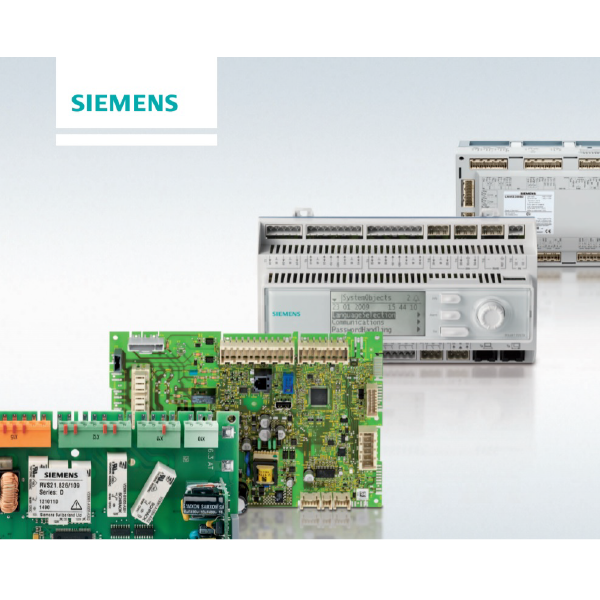

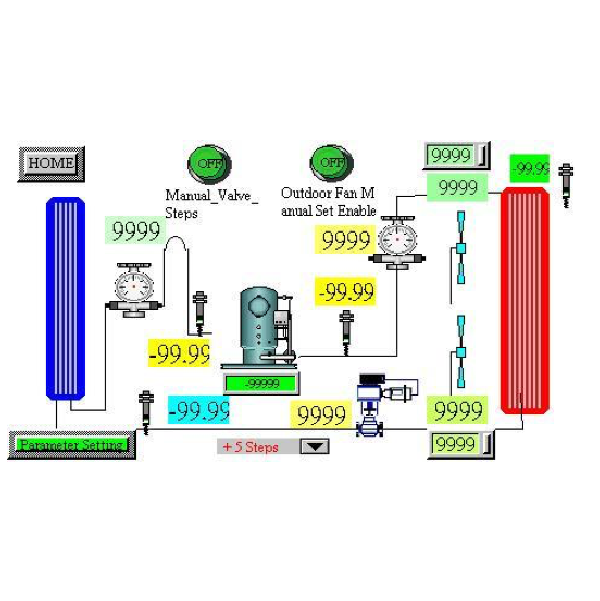

B. Implement Siemens industrial PLC and Touch Screen Interface

C. Integrate electronic expansion valve, water valve, pressure sensors, temperature sensors, humidity sensors, CO2 sensors, DC or EC Fan and DC inverter compressors into precision cooling or constant temp. & Humidity control system.

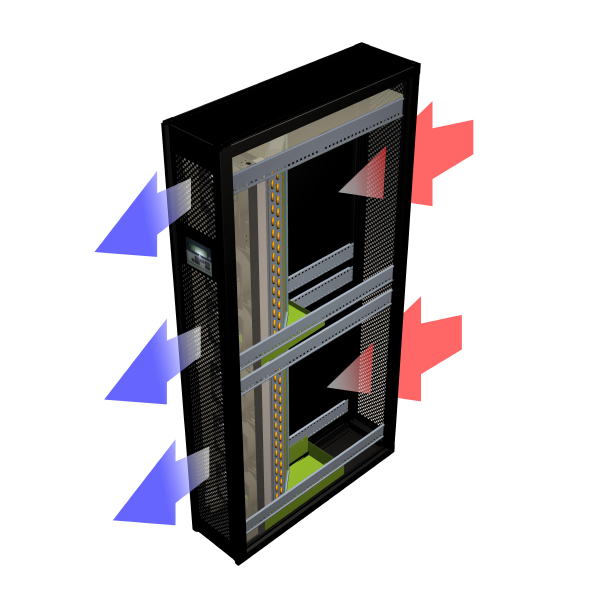

D. Apply for server room temp. & humidity control, cultivation room constant temp. & humidity control

E. Integrate communication module, support Modbus RTU, VNC, Email Alarm

F. Heat Exchange: Air cool /Water heat exchange cool

G. Capacities: 9.3KW;10.4KW;11.6KW;14.5KW;17.4KW

H. More detail spec: please send email:ken88chiang@gmail.com

Our Products:

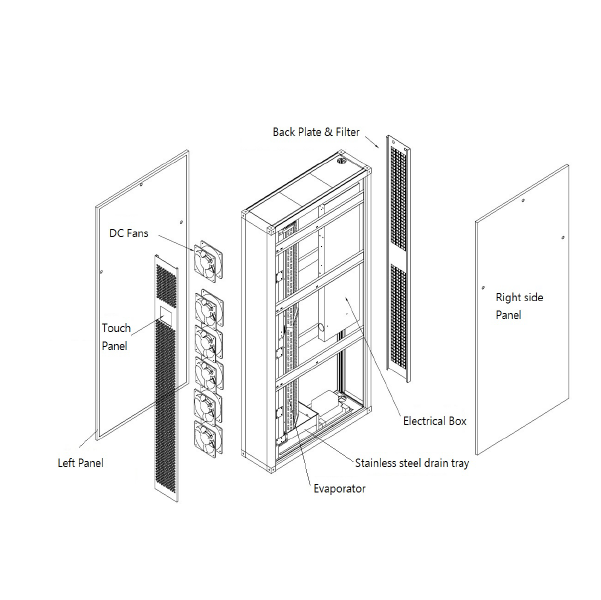

Server Room precision cooling

Server Room precision cooling

|

|

| Norminal Capacity | 10.4 KW (4.8KW~11.6KW) |

| Control Unit | Siemens Industrial PLC |

| Human Interface | 4.3” Touch Panel, Support VNC Connection |

| Data Storage | Support Micro SD up to 16G for Temp. Event record |

| Fans | DC Fans * 6 Pcs (Up to 3,000 CFM) according to heat load |

| External Temp. Sensors | 2 External Sensors for upper and lower temp. transmition |

| Refrigrant System Protection | Refrigrant High Pressure / Low Pressure Switches |

| Group Operation Management System | Group Operation up to 4 InRow Systems. Support Scheduling, backup operation,temp. or event trigger operation |

| Communication Module | Support Modbus RTU |

| Size | H 2,025mm * W 300mm *D 1,000/1,200mm |

| Heat Exchange (Air Cool) | |

| Compressor | Mitsubishi DC Inverter Compressor |

| Expansion Valve | Electronic Expansion Valve |

| Pressure Sensors | 2 Pressure Transmitter |

| Fans | DC Fans |

| Temp. Sensors | 5 Temp. Sensors for monitoring and controlling |

| Size | H 1,290mm * W 1,050mm *D 420 mm |

| Power | 220V, 50/60 Hz |